Leaf Tree’s tool-free and modular assembly is made possible by the use of gravity-secured cleats (shortened to gravity cleats). Each Leaf has a heel and toe section that work together to clamp onto the Trunk by sliding it onto the tree at an upward angle and flattening it when the desired position is reached.

The original gravity cleats were made from 1/2 inch birch plywood with a smooth inner surface to clamp against the Trunk. This design easily maintained the set height of the leaf, but when leapt off of, or bumped into, they would very easily shift around the Trunk.

To mitigate the horizontal shift, we initially tried using rubber tape on the inside of the gravity cleat to increase friction, the results were far from ideal, but the additional friction was the right direction! The next test was to make the gravity cleat itself texturized. The first attempt was done completely by hand using a router…

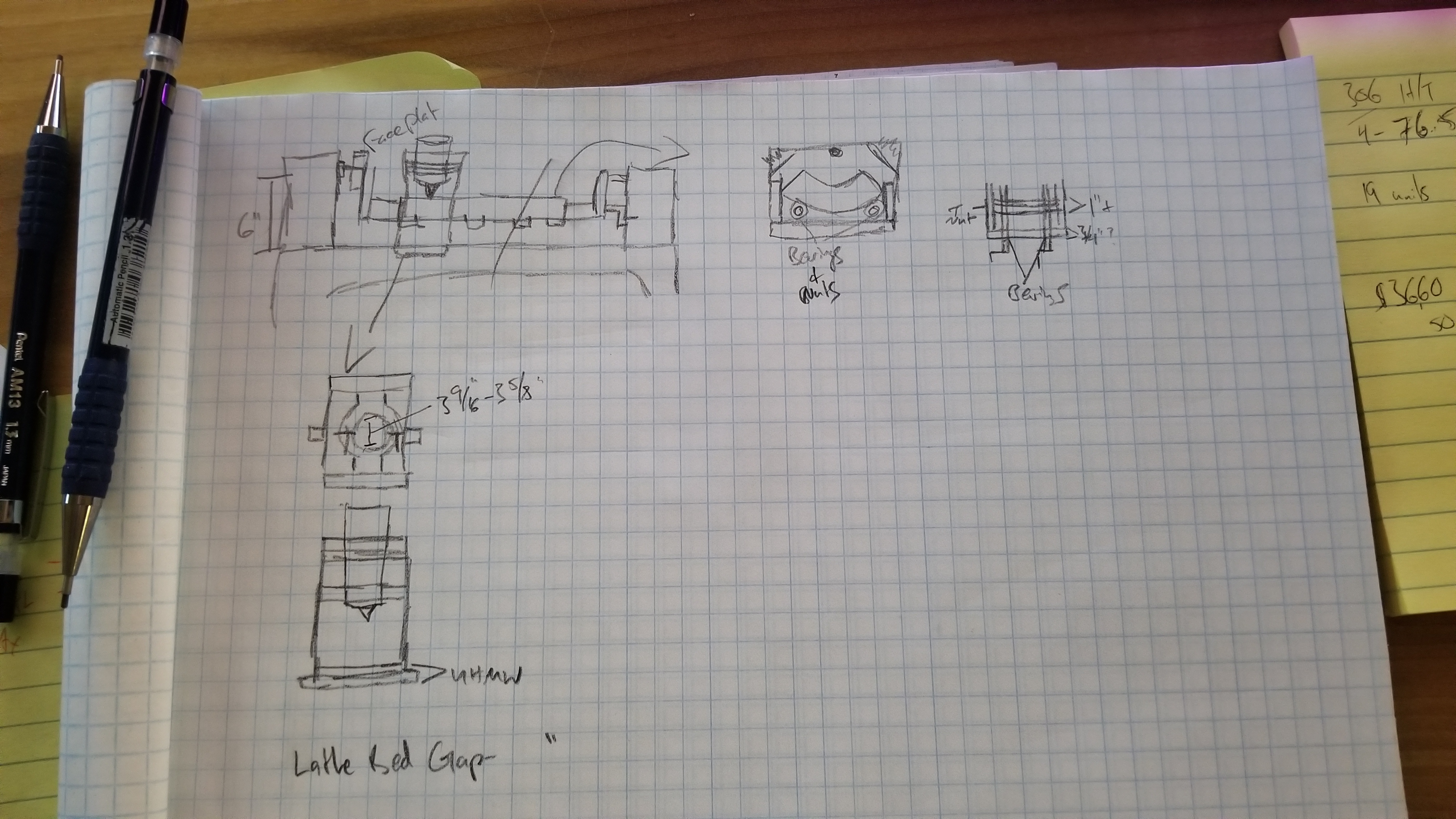

…The process was time-consuming and arduous, and worst of all: the final result was not worth all that effort! So the next step was to design a jig to make the process more consistent.

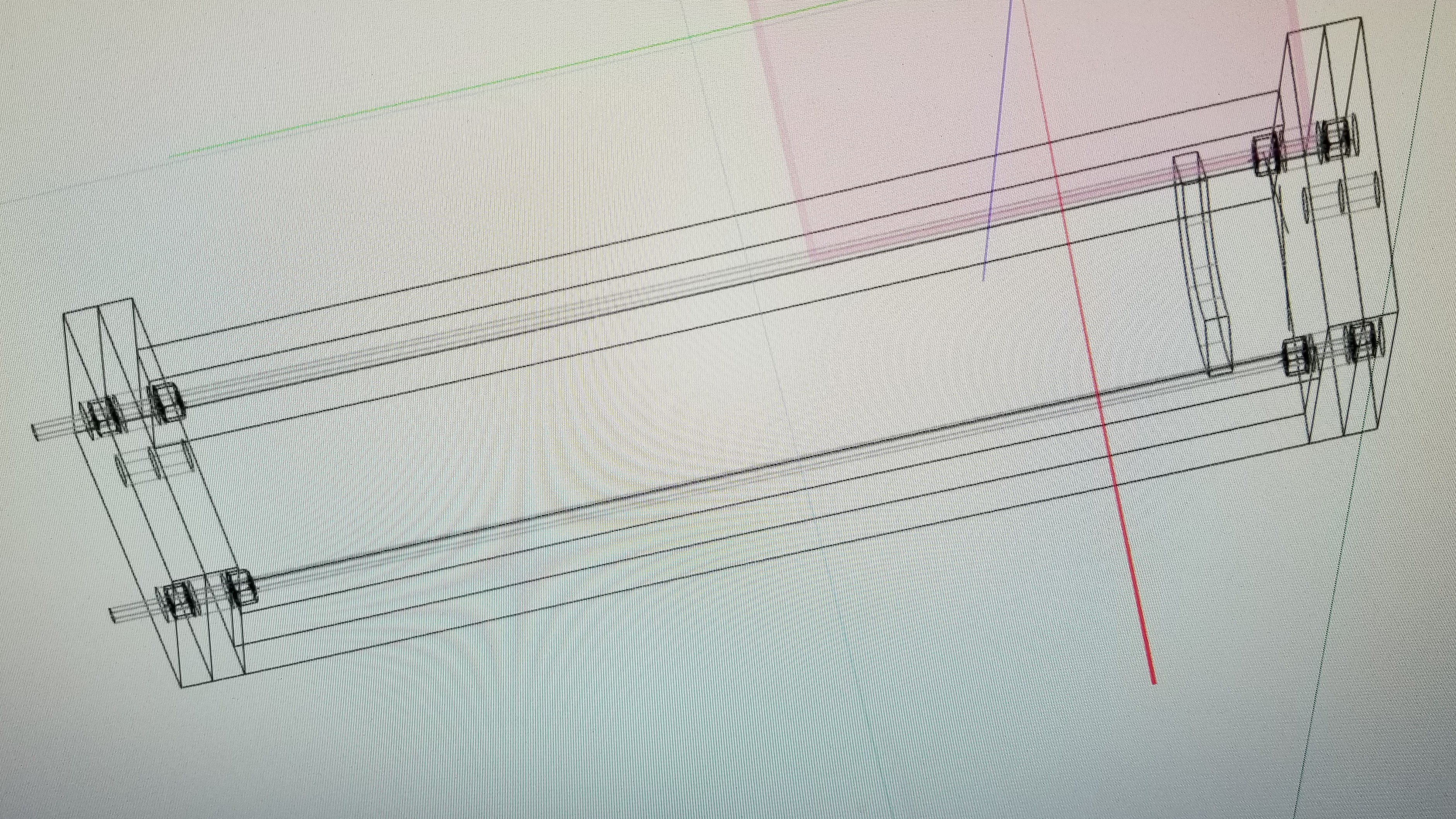

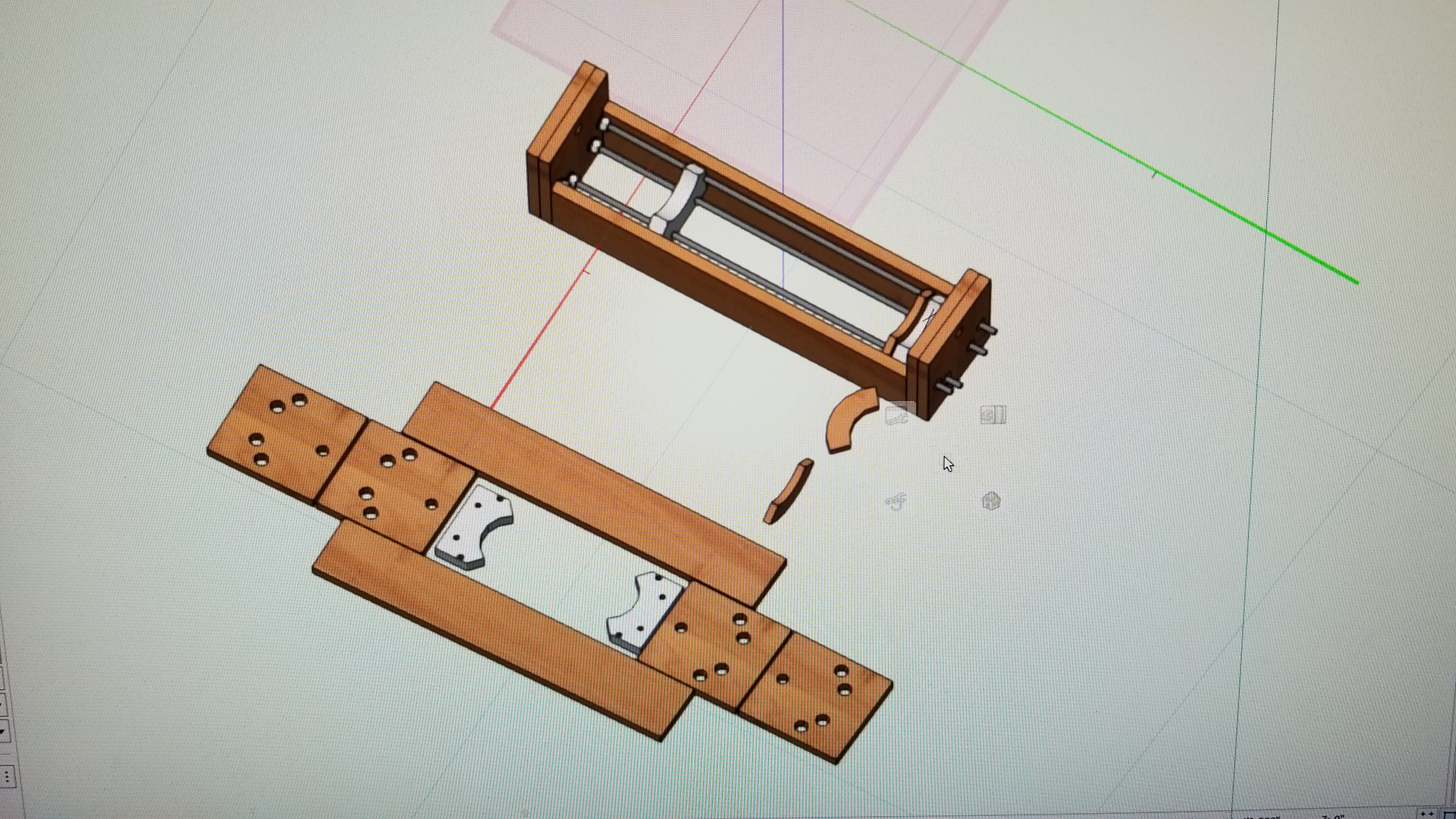

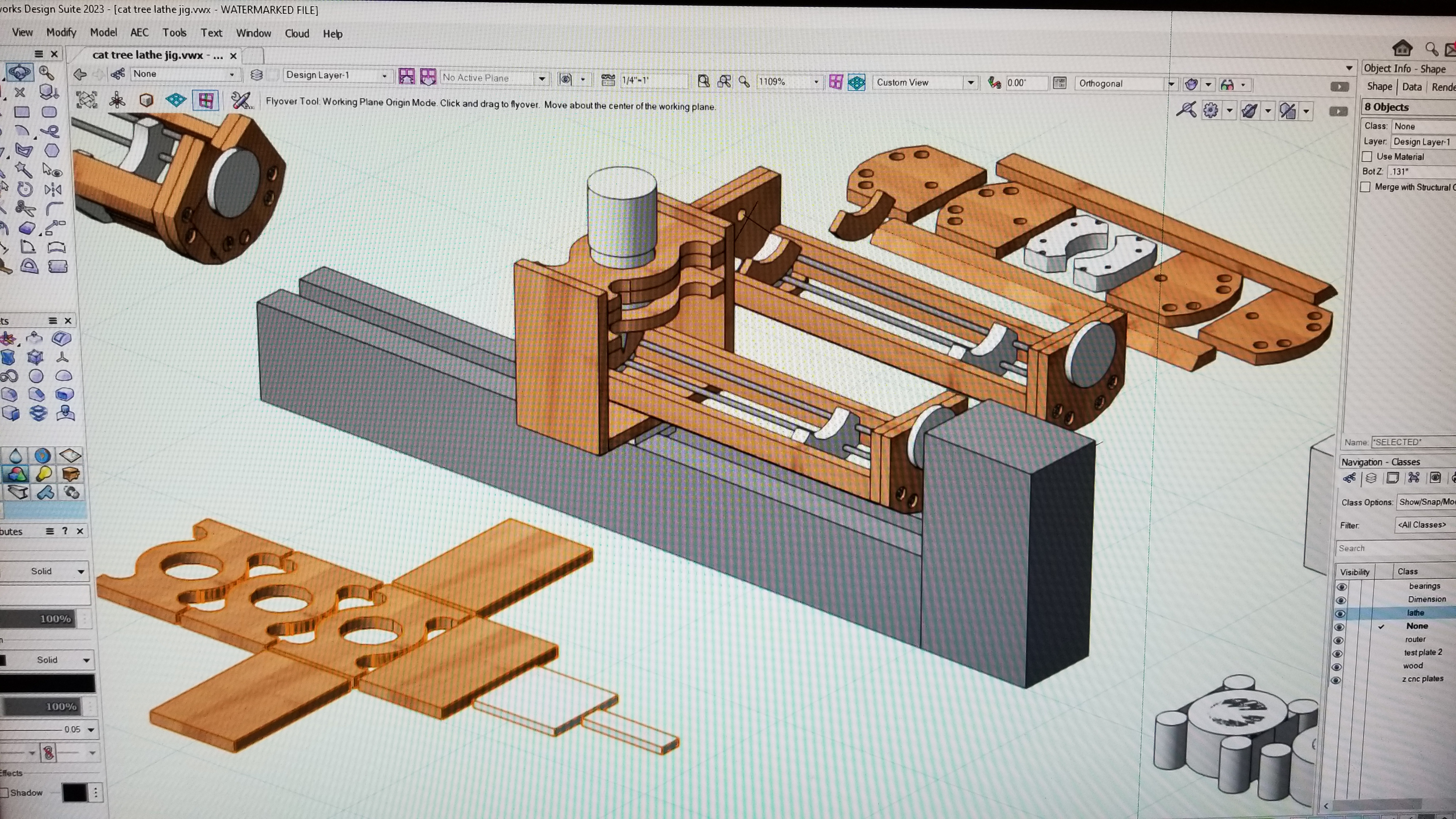

After the initial rough sketch and subsequent CAD mockup, the jig parts were cut from 3/4 inch birch* plywood using a CNC router and assembled using 3/8 inch threaded rod, nuts, washers, bearings, and screws. The jig is designed to hold multiple cleat pieces to cut consistent pyramidal shapes using a hand-router that’s mounted to the jig.

*The plywood we received was actually plywood with a balsa core and birch veneer (quite unideal)

After assembly, the jig was mounted to an indexing lathe to take advantage of two axis of cutting along three axis of movement.

After completing all of the passes to cut the desired pyramidal pattern, two of the final cleat parts were temporarily secured to a Leaf using clamps to determine the proper spacing of the heel and toe placements to achieve the ideal clamping action.

Once the position was dialed in, the heel and toe were attached to a Leaf using 4 staples and 4 screws to create Leaf Mk2!

Leave a comment